When the finished wire meshes leave our DGS production halls, they must often be cleaned before further processing. On the machinery also during subsequent processing residues of oil and particles are left on the metal products.

These can become a problem later during further processing, if they are not removed: but if the metal is painted, coated or glued, it should really be free of grease. When materials are exposed to high temperatures, residues produced during processing can result in disagreeable odours. And in the field of e-mobility for example, it would be fatal if small particles or impurities on the metal parts triggered a short circuit. Of course, components should be as clean as possible, particularly in food and medical areas as well.

At DGS we take care of the cleaning and degreasing of our wire products ourselves. Thus we are flexible as to the time frame and can guarantee products of perfect quality. By means of solvents and subsequent vacuum drying our industrial cleaning machines remove oil, grease and remnants of other elements as well as any particle residues of the solvent.

It is true that a one hundred percent cleanliness is technically not possible, yet we can exclude particle residues up to a defined size from the end product. Besides that, we are one of the few companies, who have set up our own laboratory. This means, after cleaning, we can produce a detailed analysis of any of the remaining issues.

Additional services:

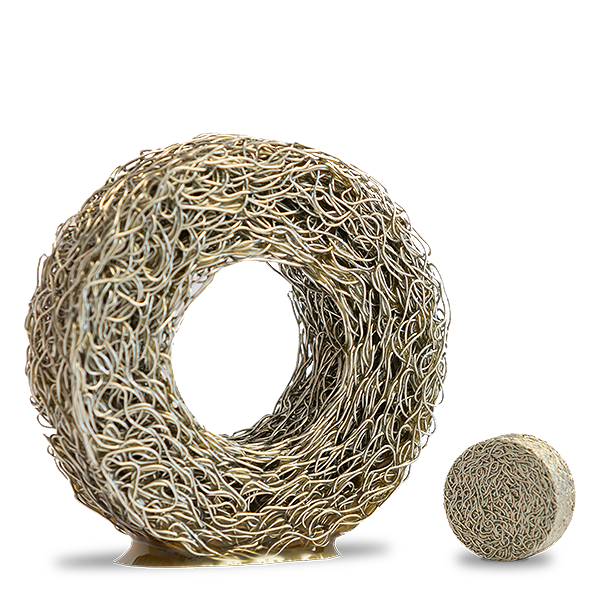

with production residues

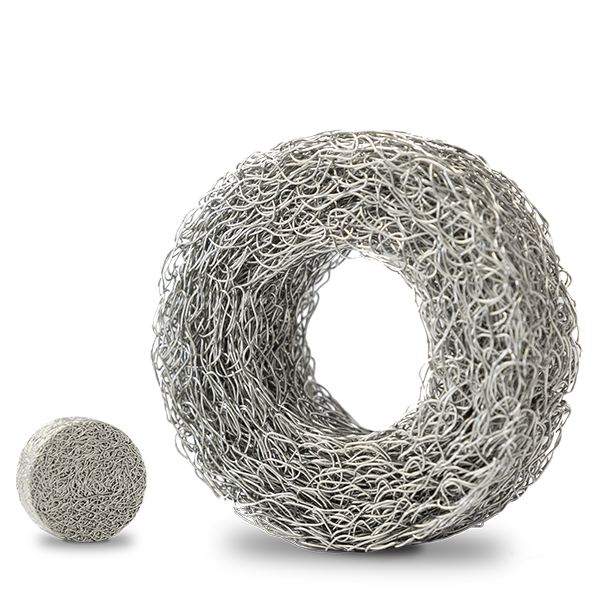

cleaned

We will be happy to help you and provide you with a non-binding and free quote.

DGS DRAHTGESTRICKE GMBH

OPENING HOURS

© 2022 DGS Drahtgestricke GmbH